Plastic Types for Pharmaceutical Vials and Bottles

Plastic is an essential component of numerous consumer products, including prescription vials, bottles and caps. However, not every kind of plastic is the same. In 1988, the Society of the Plastics Industry (SPI) established a classification system to help consumers and recyclers properly recycle and dispose of each different type based on its chemical makeup. Today, manufacturers follow a coding system and place a number, or SPI code, on each plastic product, usually molded into the bottom. Although you should always verify the plastic classification number of each product you use, especially if you plan on recycling it, this guide provides a basic outline of the different plastic types associated with each code number.

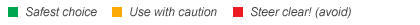

The following graphic is a quick summary of the plastics labels and their “threat” level.

Plastic vials and bottles come in a variety of materials (resins). Plastic vials and bottles produced from HDPE material are the most common and least expensive. Plastic vials and bottles produced from PET material are crystal clear. Plastic jars produced from PP material are resilient and economical. Plastic Jars made from PS are clear. All of our plastic vials and bottles are FDA approved food grade.

Recycling has been aided by the creation of The Plastic Bottle Material Code System. This system is designed to be easy to read at a glance and distinguishable from any other marking on the bottom of a container. Where this system is in place, these symbols are required to appear on all bottles 8 oz. and greater.

The symbol consists of a triangle formed by three "chasing arrows", with a specific number in the center that indicates the material from which the bottle is made. The number/material equivalents are:

The number code is then supplemented by the common letter indication for the various resins under the symbol, to serve as a constant verification of the material sorted.

Plastic #1: Polyethylene terephthalate (PET or PETE):

Properties: clarity, lightness, strength, toughness, barrier to liquid and gas.

Properties: clarity, lightness, strength, toughness, barrier to liquid and gas.

Plastic marked with an SPI code of #1 is made with polyethylene terephthalate, which is also known as PETE or PET. PET is a thermoplastic that can be drawn into fibers (like Dacron) and films (like Mylar).

PETE-based containers sometimes absorb odors and flavors from foods and drinks that are stored inside of them.

Recycled PETE is used to make tote bags, carpet, fiberfill material in winter clothing, and more.

Typical Use:

PETE plastic is used to make many common household items like:

Bottles (water, soft drink, juice, beer, wine, mouthwash, salad dressing), peanut butter/jam jars, oven-ready and microwaveable meal trays, detergent and cleaner containers. Also used in liquid crystal displays, film for capacitors, insulation for wire and insulating tapes, and as a common finish for wood products such as guitars, pianos and vehicle/yacht interiors.

PET fabric (polyester) is commonly used in textiles (fabric and clothing), padding and insulation (for pillows, comforters, upholstery), carpet, and mouldings. Also for tyre reinforcements, conveyor belts, safety belts, coated fabrics and tarpaulins.

Many personalized toys are made from this plastic as well.

|

|

|

||||||

Toxicity:

Usually clear in color, This plastic is considered generally safe and is picked up by most curbside recycling programs. However, the porous nature of its surface allows bacteria and flavor to accumulate, so avoid reusing these bottles as makeshift containers.

PET may leach antimony (antimony trioxide is used as a catalyst and flame retardant in PET). The longer a liquid is left in a PET container the greater the potential for release. As well, warm temperatures inside cars, garages, and enclosed storage areas increase the release of antimony into the liquid. Antimony trioxide is considered a possible carcinogen. Workers exposed to antimony trioxide for long periods of time have exhibited respiratory and skin irritation and among female workers, increased incidence of menstrual problems and miscarriage -- while there is no evidence that these effects could arise from exposure to the small amounts of antimony released from PET products (such as water bottles), we prefer not to be exposed to it at all.

Evidence is also emerging that phthalate endocrine disruptors also leach from PET.

PET as a textile - i.e., polyester - likely contains flame retardants incorporated into it during the manufacturing process. As such, polyester is often described as "inherently flame retardant", but it is unclear exactly which flame retardant chemicals are added to polyester as it is being made, and thus it is difficult to know if there is a toxicity issue with polyester fibre.

Our Suggestion:

AVOID. Many consider PET a relatively safe single use plastic, but given the research indicating it can release antimony and phthalates, and our precautionary approach, we suggest avoiding it whenever possible. If you must use it, keep it away from heat and do not reuse it.

Plastic #1 is only intended for one time use.

Plastic #2: Polyethylene, HDPE

Properties: stiffness, strength, toughness, resistance to moisture, permeability to gas, ease of processing.

The SPI code of #2 identifies plastic made with high-density polyethylene, or HDPE.

Usually opaque in color and picked up by most recycling programs..

Recycled HDPE is used to make plastic crates, plastic lumber, fencing, and more.

In the 1950s, Karl Ziegler polymerized ethylene in the presence of various metals. The resulting polyethylene polymer was composed of mostly linear polymers. This linear form produced tighter, denser, more organized structures and is now called high-density polyethylene (HDPE). HDPE is a harder plastic with a higher melting point than LDPE, and it sinks in an alcohol-water mixture. HDPE was first introduced in the hula hoop, but today it's mostly used in containers.

Typical Use:

Plastic bags (grocery), opaque milk, water, and juice containers, bleach, detergent and shampoo bottles, garbage bags, dishes, yogurt and margarine tubs, cereal box liners, some medecine bottles. Also used in Tyvek insulation, PEX piping, plastic/wood composites.

|

|

|

||||||

Toxicity:

This plastic is considered safe and has low risk of leaching. HDPE products is not known to leach any chemicals into foods or drinks. However, due to the risk of contamination from previously held substances, Please note: it is NEVER safe to reuse an HDPE bottle as a food or drink container if it didn’t originally contain food or drink! HDPE products are commonly recycled.

Being relatively stable, it is generally considered a safer plastic for food and drink use, although some studies have shown that it can leach the endocrine disruptor nonylphenol (added to HDPE as a stabilizer), especially when exposed to ultraviolet light - i.e., sunlight - and possibly other additive chemicals with estrogen-mimicking activity.

Our Suggestion:

RELATIVELY SAFE. But has been shown to release endocrine disrupting chemicals.

Plastic #3: Polyvinyl Chloride (PVC):

Properties: versatility, ease of blending, strength, toughness, clarity, transparency.

Properties: versatility, ease of blending, strength, toughness, clarity, transparency.

Plastic labeled with an SPI code of #3 is made with polyvinyl chloride, or PVC.

It is used to make food wrap, bottles for cooking oil, and the highly common plumbing pipes. PVC, although tough in terms of strength, it is not considered safe to cook food near it. PVC contains softening chemicals called phthalates that interfere with hormonal development. Never cook using food wrap, especially in a microwave oven.

This plastic is rarely accepted by recycling programs, is not often recycled.

PVC and can be harmful if ingested. PVC is used for all kinds of pipes and tiles, but it's most commonly found in plumbing pipes. This kind of plastic should not come in contact with food items.

Recycled PVC is used to make flooring, mobile home skirting, and other industrial-grade items.

PVC is a thermoplastic that is formed when vinyl chloride (CH2=CH-Cl) polymerizes. When made, it's brittle, so manufacturers add a plasticizer liquid to make it soft and moldable. PVC is commonly durable, can't be corroded and is cheaper than metal pipes. Over long periods of time, however, the plasticizer may leach out of it, rendering it brittle and breakable.

Typical Use:

Soft PVC (softened with plasticizers) used in toys, clear food (e.g., take-out) and non-food packaging (e.g., blister wrap, cling wrap), squeeze bottles, shampoo bottles, mouthwash bottles, cooking oil and peanut butter jars, detergent and window cleaner bottles, loose-leaf binders, shower curtains, blood bags and medical tubing, "pleather" clothing, Naugahyde upholstery, wire and cable insulation, carpet backing and flooring. Rigid PVC used for blister packs and clamshell packaging, credit cards, piping (e.g., for plumbing), vinyl siding, window frames, fencing, decking, and other construction materials.

|

||||

Toxicity:

PVC is widely considered the most toxic and hazardous plastic that is still - unbelievably so - commonly used to make numerous consumer products (PVC1, PVC2). It may contain and/or leach a variety of toxic chemicals including, but not limited to: bisphenol A (BPA), phthalates, lead, dioxins, mercury, and cadmium.

When PVC is burned (e.g., via waste incineration, car or home fires), dioxins are formed. Dioxins are known human carcinogens and persistent organic pollutants, and are considered one of the most toxic types of chemicals ever tested (PVC1, PVC11).

Our Suggestion:

AVOID. At all costs. Can be extremely toxic.

Plastic #4: Polyethylene, LDPE:

Properties: strength, toughness, flexibility, resistance to moisture, ease of sealing, ease of processing.

Properties: strength, toughness, flexibility, resistance to moisture, ease of sealing, ease of processing.

is used to make grocery bags, some food wraps, squeezable bottles, and bread bags. While considered safe it is unfortunately not often accepted by curbside recycling programs.

Plastic marked with an SPI code of #4 is made with low-density polyethylene, or LDPE. LDPE is not commonly recycled, but it is recyclable in certain areas. It tends to be both durable and flexible. It also is not known to release harmful chemicals into objects in contact with it, making it a safe choice for food storage. Plastic cling wrap, sandwich bags, squeezable bottles, and plastic grocery bags all are made from LDPE. Recycled LDPE is used to make garbage cans, lumber, furniture, and many other products seen in and around the house.

The most common polymer in plastics is polyethylene, which is made from ethylene monomers (CH2=CH2). The first polyethylene was made in 1934. Today, we call it low-density polyethylene (LDPE) because it will float in a mixture of alcohol and water. In LDPE, the polymer strands are entangled and loosely organized, so it's soft and flexible. It was first used to insulate electrical wires, but today it's used in films, wraps, bottles, disposable gloves and garbage bags.

Typical Use:

Mostly for film applications like bags (grocery, dry cleaning, bread, frozen food bags, newspapers, garbage), plastic wraps; coatings for paper milk cartons and hot & cold beverage cups; some squeezable bottles (honey, mustard), food storage containers, container lids. Also used for wire and cable covering.

|

||||

Toxicity:

Being relatively stable, it is generally considered a safer plastic for food and drink use, although some studies have shown that it can leach the endocrine disruptor nonylphenol (added to LDPE as a stabilizer), especially when exposed to ultraviolet light - i.e., sunlight - and possibly other additive chemicals with estrogen-mimicking activity (LDPE1, LDPE2).

Our Suggestion:

RELATIVELY SAFE. But has been shown to release endocrine disrupting chemicals.

Plastic #5: Polypropylene (PP):

Properties: strength, toughness, resistance to heat, chemicals, grease & oil, barrier to moisture.

Properties: strength, toughness, resistance to heat, chemicals, grease & oil, barrier to moisture.

This is polypropylene. Consumers will find the SPI code of #5 on plastic items made with polypropylene, or PP.

This plastic is also considered safe, and is increasingly being accepted by curbside recycling programs. PP can be recycled but is not accepted for recycling as commonly as PETE or HDPE. This type of plastic is strong and can usually withstand higher temperatures (< 167¡æ).

Recycled PP is used to make ice scrapers, rakes, battery cables, and similar items that need to be durable.

In 1953, Karl Ziegler and Giulio Natta, working independently, prepared polypropylene from propylene monomers (CH2=CHCH3) and received the Nobel Prize in Chemistry in 1963. The various forms of polypropylene have different melting points and hardnesses. Polypropylene is used in car trim, battery cases, bottles, tubes, filaments and bags.

Typical Use:

Food containers (ketchup, yogurt, cottage cheese, margarine, syrup, take-out), medicine containers (prescription bottles, plastic prescription vials and caps), straws, bottle caps, Britta filters, Rubbermaid and other opaque plastic containers, including baby bottles. Other uses include disposable diaper and sanitary pad liners, thermal vests, appliance parts and numerous car parts (bumpers, carpets, fixtures).

|

|

|

||||||

Toxicity:

Being relatively stable, it is generally considered a safer plastic for food and drink use, although it has been shown to leach plastic additives (such as the stabilizing agent oleamide) when PP labware was used in scientific experiments (PP1) and one older study has suggested heated PP may be linked to occupational asthma based on the exposure of a worker in a PP factory (PP2).

Our Suggestion:

RELATIVELY SAFE. But has been shown to release additive chemicals when used as labware in scientific experiments.

Plastic #6: Polystyrene, (PS, Styrofoam)

Properties: versatility, clarity, easily formed.

Properties: versatility, clarity, easily formed.

Plastic marked with an SPI code of #6 is made with polystyrene, also known as PS and most commonly known as Styrofoam. PS can be recycled, but not efficiently; recycling it takes a lot of energy, which means that few places accept it.

Overwhelming evidence suggests that this type of plastic leaches potentially toxic chemicals, especially when heated.

Recycled PS is used to make many different kinds of products, including insulation, license plate frames, and rulers.

Polystyrene is formed by styrene molecules. The double bond between the CH2 and CH parts of the molecule rearranges to form a bond with adjacent styrene molecules, thereby producing polystyrene. It can form a hard impact-resistant plastic for furniture, cabinets (for computer monitors and TVs), glasses and utensils. When polystyrene is heated and air blown through the mixture, it forms Styrofoam. Styrofoam is lightweight, moldable and an excellent insulator.

Typical Use:

EPS: Styrofoam food containers, egg cartons, disposable cups and bowls, take-out food containers, deli food plates, packaging, packing peanuts, bike helmets. Harder clear/opaque PS: disposable cutlery & razors, compact disc & dvd cases. High impact PS: hangers, smoke detector housing, licence plate frames, medecine bottles, test tubes, petri dishes, model assembly kits.

|

|

|

||||||

Toxicity:

PS food containers can leach styrene, which is reasonably anticipated to be a human carcinogen (PS1, PS2) and is considered a brain and nervous system toxicant (PS1, PS3, PS4). Animal studies have shown adverse effects on genes, lungs, liver, and the immune system (PS2). Note that styrene is also present in second-hand cigarette smoke, off-gassing building materials, and car exhaust. The leaching of styrene from PS containers into food is increased when the food or liquid is hot and oily (PS3, PS4) .

Our Suggestion:

AVOID. Can leach styrene, which is a brain and nervous system toxin and likely carcinogenic.

Plastic #7: Others

The SPI code of #7 is used to designate miscellaneous types of plastic that are not defined by the other six codes. Polycarbonate and polylactide are included in this category. Plastic CDs and DVDs These types of plastics are difficult to recycle. Polycarbonate, or PC, is used in baby bottles, large water bottles (multiple-gallon capacity), compact discs, and medical storage containers. Recycled plastics in this category are used to make plastic lumber, among other products.

The SPI code of #7 is used to designate miscellaneous types of plastic that are not defined by the other six codes. Polycarbonate and polylactide are included in this category. Plastic CDs and DVDs These types of plastics are difficult to recycle. Polycarbonate, or PC, is used in baby bottles, large water bottles (multiple-gallon capacity), compact discs, and medical storage containers. Recycled plastics in this category are used to make plastic lumber, among other products.

This category basically means “everything else” and is composed of plastics that were invented after 1987 – the use of plastic in this category is at your own risk since you don’t know what could be in it. Polycarbonate falls into this category, including the highly toxic BPA. Products produced include baby and water bottles, sports equipment, medical and dental devices, CD’s, DVD’s, and even iPods. It is wise to dispose of any food or drink related product that is known to contain BPA. It is difficult to recycle #7 plastic and most curbside recycling programs won’t accept it.

To summarize, plastics in categories #2, #4 and #5 are generally considered safe. Plastic #1 is safe but should not be re-used due to the risk of growing bacteria. Any of the other categories should be used with extreme caution, especially around food or drink, and the risk is even greater when heating food. For microwaving, know that microwave safe containers aren’t necessarily healthy, they just won’t melt. Do yourself, your body, and the environment a favor – avoid plastic entirely and stick to glass when you can.